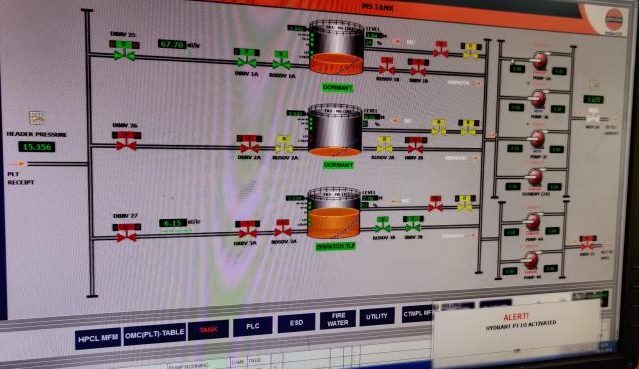

The control room in a terminal is analogous to nucleus of cell.It is the coordinating and monitoring center of the terminal.

The combination of hardware,software and networking helps us to monitor and control various parameter of the terminal like flow rate,valve status,fire protection system,tank status,etc.

They consist of Programmable Logic Controller(PLC) which are connected to various sensing devices via input module .They sense parameters like pressure,level ,temperature ,ON-OFF status of valve and send it to PLC.The PLC is programmed to take suitable action as per input recieved which is being programmed in it.The action is implemented in terminal using output module.

Some of the components of control room are given below :

- Tank number

- Average temperature

- Flow Rate

- Total volume

- Density

- READINGS OF PRIMARY AND SECONDARY RADAR GAUGE

- ROSOV,DBBV,PUMP status

- RED-CLOSED/STOP

- GREEN-OPEN/IN OPERATION

- FLOW MECHANISM

- TANK STATUS viz, DISPACTH,RECIEPT,DORMANT

- ETHANOL TANK STATUS

- TANK DIP IN mm

- DENSITY

- TEMPERATURE

- PUMP STATUS

- HIGH LEVEL ALARM

- VALVE ON-OFF STATUS

- FUEL ADDITIVE TANK STATUS viz. XTRAPREMIUM(MS) AND XTRAMILE(HSD)

- ADDITIVE PUMP STATUS

- TANK STATUS

- RECIEPT AND DISPATCH VALVE STATUS

- PIPELINE VALVE STATUS

- RECIRCULATION VALVE STATUS

- DISPATCH AND PIPELINE PUMP STATUS

- STATUS OF PIPELINE TO HPCL

DYKE VALVE STATUS OF ALL ABOVE GOUND TANKS

- WATER TANK LEVEL

- JOCKEY PUMP STATUS

- BOREWELL PUMP STATUS

- OWS PUMP STATUS

- SUMP PUMP STATUS

- PRESSURE MONITOR

- FIRE ENGINE STATUS

DIESEL GENERATOR SET STATUS

MASS FLOW METER READING PRODUCTWISE

HVLR Status

Tank Status

COLOUR CODING-

RED-OFF/OPEN

GREEN-ON/CLOSED

YELLOW-IN TRANSITION